Joining materials permanently to create strong, reliable structures is a specialised activity that demands careful oversight. This joining method plays a vital role across numerous sectors, from constructing pressure vessels to manufacturing aerospace components.

The complexity of these joining operations varies significantly depending on the application. Each project requires specific equipment and skilled personnel who possess the necessary training and expertise. This ensures the final product meets the desired mechanical and structural properties.

Proper validation of methods serves as a crucial quality assurance mechanism. It verifies that joining techniques comply with rigorous industry standards and safety requirements. Companies like NWQS specialise in providing these essential services.

Comprehensive documentation provides evidence that all joining work adheres to national and international specifications. This protects both manufacturers and end-users, ensuring structural integrity and long-term reliability.

Key Takeaways

- Welding is recognised as a specialised joining process requiring rigorous oversight

- Proper qualification ensures structural integrity and safety across multiple industries

- The complexity of welding varies significantly depending on application requirements

- Certification serves as a quality assurance mechanism verifying compliance with standards

- Effective processes depend on comprehensive training, experience, and technical expertise

- Documentation provides evidence that services meet national and international requirements

- Companies like NWQS Ltd offer specialised services to support qualification needs

Understanding Welding Procedure Qualification Records

Before any critical fabrication begins, the methodology for joining metals must be formally validated to ensure it meets stringent design and safety criteria. This validation is captured in a vital document known as a Welding Procedure Qualification Record (WPQR) or Procedure Qualification Record (PQR).

Overview of WPQR and Its Importance

These procedure qualification records serve as the foundational proof that a specific set of parameters can consistently create acceptable joints. They document all essential variables used during the initial qualification tests.

This documentation demonstrates the method’s capability to produce results with the required mechanical properties. Qualification records are critical for compliance, protecting manufacturers and ensuring structural integrity.

Documentation and Testing Requirements

The creation of these records involves a meticulous process. Qualified examiners visit sites to collect all necessary data. They coordinate comprehensive testing with independent, accredited laboratories.

This testing verifies the quality of the joint through two main methods:

- Non-destructive testing (e.g., radiographic or ultrasonic inspection)

- Destructive testing (e.g., tensile and bend tests)

All results are compiled against the relevant specification. Once approved, the final certification package, including the formal WPQR certificate, is issued to the welder or fabricator.

Exploring the Welding Procedure Qualification and Certification Process

Industrial fabrication demands a rigorous validation pathway that confirms operational methods meet exacting standards. This systematic approach ensures consistent quality across all metal joining activities.

Step-by-Step Process Overview

The journey begins with developing a preliminary specification outlining proposed parameters. Qualified surveillance personnel then witness test operations using calibrated equipment.

They meticulously document essential variables like material specifications and thermal conditions. Technical managers with appropriate experience review all documentation against applicable standards.

This comprehensive evaluation leads to formal approval when compliance is verified. The final package includes complete test data and official certificates.

Benefits of Proper Certification

Proper validation provides manufacturers with documented evidence of capability. This reduces the risk of costly failures and subsequent rework requirements.

Independent verification enhances quality assurance systems significantly. Clients and regulatory authorities gain confidence in the operational methods employed.

Pre-qualified approaches streamline project approval processes effectively. Maintaining certified systems supports continuous improvement initiatives throughout the organisation.

Accreditation and Compliance: The Role of NWQS Ltd in Ensuring Quality

Accredited certification providers ensure manufacturing processes adhere to internationally recognised benchmarks. These organisations maintain rigorous oversight of technical operations.

Maintaining Safety and Industry Standards

Recognised Third Party Organisations (RTPOs) authorise approval of skilled personnel and operational methods. This designation ensures compliance with critical regulations like the Pressure Equipment (Safety) Regulations 2016.

Equipment operating above 0.5 bar pressure requires mandatory certification. Proper validation prevents potential safety incidents through systematic quality assurance.

| Accreditation Aspect | Minimum Requirement | NWQS Ltd Standard | International Benchmark |

|---|---|---|---|

| Personnel Competence | Basic qualification | Advanced skill verification | ISO 9606 standards |

| Equipment Validation | Periodic checks | Continuous monitoring | EN ISO 15614 |

| Documentation Compliance | Basic records | Comprehensive audit trails | PED 2014/68/EU |

“Independent verification forms the foundation of industrial safety, ensuring methods meet statutory requirements before implementation.”

NWQS Ltd maintains consistent evaluation frameworks across all assessment services. Their approach guarantees that personnel demonstrate necessary competence in accordance with relevant standards.

This comprehensive service directly contributes to workplace safety and public protection. It particularly benefits pressure equipment applications where failures could have serious consequences.

Technical Standards and Testing Procedures

A robust framework of international standards governs the technical validation of metal joining operations. These specifications ensure consistency, quality, and safety across different industrial applications. Adherence to these benchmarks is fundamental for reliable fabrication.

ISO, DIN and International Compliance

Key international standards provide the foundation for technical approval. ISO 15614 specifies the essential testing and documentation needed to validate a weld procedure.

Complementary standards like ISO 3834 set comprehensive quality requirements for fusion joining of metals. Sector-specific specifications, such as ISO 1090 for steel structures, build upon these core requirements.

DIN standards offer detailed technical guidance widely used in European practice. Together, these frameworks create a unified system for developing and qualifying operational methods.

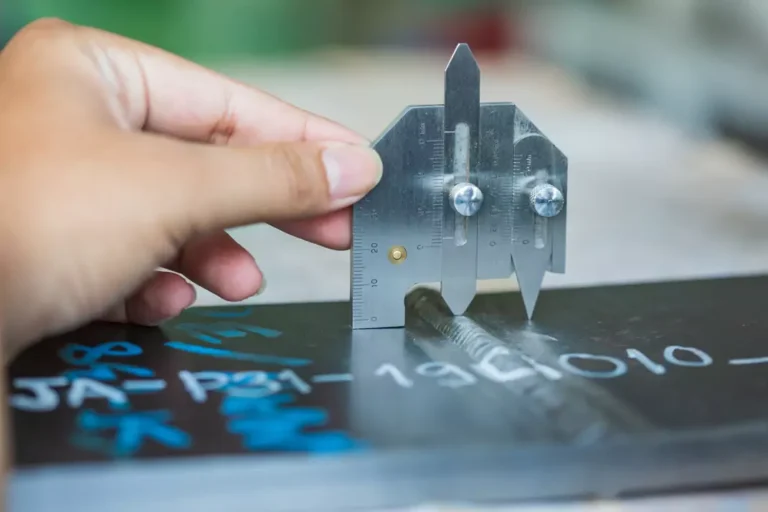

Non-Destructive and Destructive Testing Methods

Rigorous testing is critical for validation. It is conducted in two primary phases to thoroughly assess joint integrity.

First, non-destructive testing (NDT) examines test pieces without causing damage. ISO 9712 Level II certified technicians perform these evaluations using techniques like:

- Radiographic testing

- Ultrasonic inspection

- Magnetic particle inspection

Following acceptable NDT results, test coupons undergo destructive analysis. This occurs in UKAS ISO 17025 accredited laboratories.

Destructive methods include tensile tests for strength and bend tests for ductility. This comprehensive approach confirms that the final product possesses the required mechanical properties for its intended service.

Industry Applications and Expert Support by NWQS

Expert validation services support diverse industries with complex fabrication requirements and strict regulatory frameworks. The range of sectors benefiting from these essential services includes energy production, transportation, and heavy manufacturing.

Specialist personnel provide comprehensive support across multiple applications. Their expertise ensures compliance with sector-specific standards and technical requirements.

Sector-Specific Challenges and Solutions

Different industries present unique technical demands. Energy sectors require methods capable of withstanding extreme conditions and corrosive environments.

Nuclear applications demand exceptionally stringent quality standards. Extensive documentation and traceability ensure component integrity throughout service life.

Transportation sectors need compliance with specific standards like ISO 15085. These govern structural components in railway vehicle construction.

| Industry Sector | Primary Challenge | Key Standard | NWQS Support Focus |

|---|---|---|---|

| Oil & Gas | High-pressure equipment | PED 2014/68/EU | Pressure vessel validation |

| Nuclear | Safety-critical components | RCC-M | Documentation traceability |

| Aerospace | Advanced materials | EN 9100 | Specialist material expertise |

| Renewable Energy | Cyclic loading endurance | ISO 3834 | Long-term performance validation |

Training and Continuous Improvement Initiatives

The experienced team at NWQS provides ongoing technical guidance. They help clients develop effective methods and maintain qualifications.

Regular skills assessment ensures welding operators maintain competence. This adapts to evolving technologies and techniques.

Clients should please contact specialist teams for specific requirements. Early engagement addresses sector challenges effectively.

Comprehensive services support the complete validation lifecycle. From initial development through ongoing maintenance, the team delivers expert assistance.

For detailed information about validation services, please contact the certification department. They provide guidance tailored to specific industry needs.

Conclusion

Ensuring structural integrity through validated operational methods remains paramount in modern industrial practice. The qualification process provides documented evidence that fabrication techniques meet rigorous design requirements.

This systematic approach benefits multiple stakeholders by delivering defensible quality assurance. Manufacturers gain confidence in their operational capabilities while clients receive verified product integrity.

Effective validation depends on comprehensive testing and adherence to international standards. As technology evolves, these fundamental principles maintain their essential role in quality management.

Organisations should prioritise proper certification as an investment in safety and long-term success. Partnering with accredited bodies ensures access to technical expertise and regulatory knowledge.

FAQ

What is the purpose of a Welding Procedure Qualification Record (WPQR)?

A WPQR provides documented evidence that a specific weld procedure produces joints meeting the required quality standards. It is essential for demonstrating compliance and ensuring the safety and integrity of the final product.

How does the certification process work for personnel?

The process involves theoretical and practical examinations to verify a welder’s or operator’s skill. Successful candidates receive a certificate proving their competence to work on projects governed by strict specifications.

Which international standards are commonly used for qualification?

Standards like ISO 15614 are widely recognised. These frameworks set out the testing and documentation requirements to ensure global compliance and interoperability for pressure equipment and other critical fabrications.

What types of testing are involved in qualifying a weld procedure?

Both destructive and non-destructive testing methods are used. Destructive tests assess mechanical properties, while non-destructive techniques, such as radiography, check for internal defects without damaging the component.

Why is third-party approval from a body like NWQS Ltd important?

Independent verification adds a crucial layer of credibility. It assures clients and regulators that all work meets the highest industry benchmarks for safety and quality, reducing risk and facilitating project approval.

What support is available for companies new to these requirements?

Specialist organisations offer comprehensive services, from initial consultation to managing the entire approval process. They provide expert guidance on documentation, testing, and training to achieve compliance efficiently.

Comments are closed.