Lifeless sheet of metal, cold and unyielding under the factory lights. Now, picture that same sheet undergoing a kind of metallic alchemy—stretched, slit, and transformed into a strong, airy, versatile diamond-patterned grid. This isn’t magic, it’s the fascinating journey of creating expanded metal mesh, a process that turns raw, solid sheets into functional, open-area wonders. From the thunderous sound of the press to the final product ready for installation, every step is a deliberate dance of engineering and material science. Let’s pull back the curtain on this industrial metamorphosis, exploring how simple sheets become the unsung heroes in architecture, industry, and safety.

From Flat to Functional: The Expansion Magic

The core of this transformation is the expanded metal mesh manufacturing process, a method that is both brilliantly simple and remarkably efficient because it creates a product from a single piece of material with no waste.

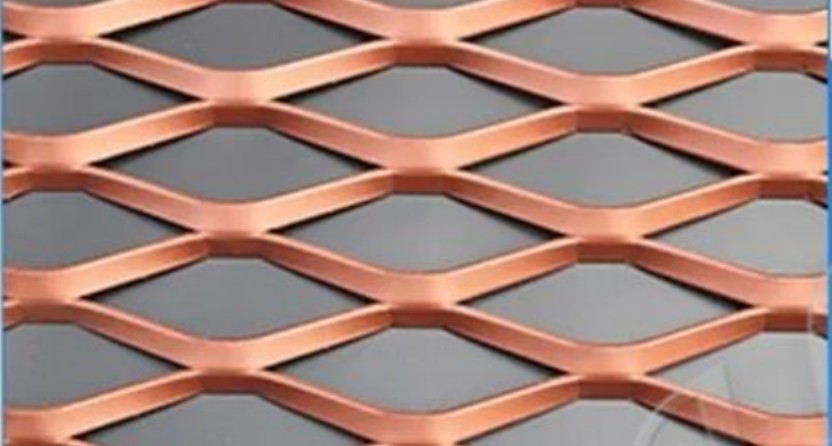

The process starts with a solid metal coil or sheet, known as the base metal. This sheet is fed into a massive expansion press. The press doesn’t cut or punch holes out in the traditional sense. Instead, it uses a die with specially shaped blades that make a staggered series of short slits into the metal. The real magic happens in the next millisecond. As the sheet advances, the press’s upper tool engages and stretches the metal, pulling these slits open into a uniform pattern of diamonds or other shapes. This simultaneous stretching and expanding is what gives expanded metal mesh its name and its unique structural advantage: because the strands and bonds are all one piece, the mesh gains tremendous strength and rigidity from the deformation of the metal itself.

What’s truly beautiful about this process is its material efficiency. Unlike perforation or weaving, which create scrap cut-outs or require multiple strands, the expansion process simply redistributes the metal. Nothing is removed. The original sheet gets larger in area but thinner in gauge, transforming every single gram of raw material into the final expanded metal mesh product. This lack of waste makes it not only cost-effective but also an appealing choice from a sustainable manufacturing perspective.

Choosing the Right Stuff: It’s All in the Material

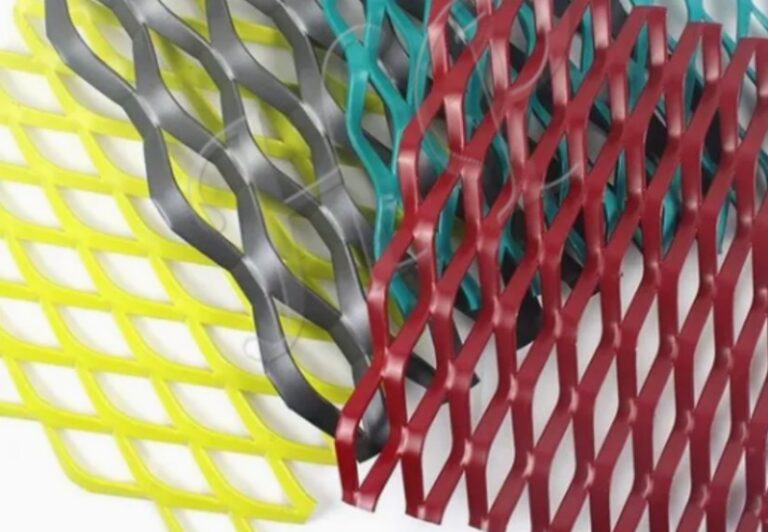

You can’t talk about the final product without diving deep into the raw ingredients. The choice of material isn’t just about color or price, it fundamentally defines where and how the expanded metal mesh will perform its job. Manufacturers like Haopeng work with a variety of metals, each bringing its own superpowers to the table.

For sheer toughness and corrosion resistance, stainless steel is the undisputed champion. When you see expanded metal mesh specified for harsh outdoor environments, chemical plants, marine applications, or high-traffic architectural features, you’re likely looking at stainless steel. It forms a passive chromium oxide layer that protects it from rust, making it last for decades with minimal maintenance. Grades like 304 or 316 are common, with 316 offering superior resistance to chlorides (like sea salt), making it perfect for coastal projects.

When weight is a major concern, aluminum steps into the spotlight. Aluminum expanded metal mesh is incredibly lightweight, naturally corrosion-resistant, and easily formed. This makes it a top choice for decorative ceiling panels, sleek interior partitions, lightweight screening, and transportation applications where every kilogram counts. It can be left in its natural silvery state, anodized into various colors (like the decorative panels mentioned on the site), or powder-coated for additional durability and aesthetic appeal.

For general-purpose, cost-effective strength, carbon steel and galvanized steel are the workhorses. Standard carbon steel expanded metal mesh is strong and great for industrial platforms, walkways, and fencing where appearance isn’t the primary concern. To combat rust, it is often galvanized—coated in a layer of zinc. This galvanized expanded metal mesh is the classic material for utility shelves, protective barriers, and industrial flooring, offering a great balance of strength, durability, and value, as seen in products like “Decorative Galvanized Perforated Metal Sheet for Stair.”

More Than Just Holes: The Shape of Performance

When you look at a sheet of expanded metal mesh, the pattern might seem purely decorative. But in reality, the geometry—the strand width, the bond points, and the opening size—is precision-engineered for performance. This is where customization truly shines.

The classic pattern is the standard or “regular” diamond. In this style, the strands are flattened, and the mesh has a raised, dimensional profile. It’s the go-to for walkways and platforms because the raised pattern provides excellent slip resistance, a critical safety feature. The bonds where the strands intersect are incredibly strong because the metal is work-hardened during stretching.

For applications requiring a smooth, flush surface, there’s flattened expanded metal mesh. After the initial expansion, the mesh is passed through a cold-rolling mill to crush the raised strands flat. This creates a smooth plane ideal for things like decorative panels (like those “Diamond 4X8 Sheet Expandable Mesh Ceiling Panel”s), filtration screens, or guards on machinery where a flat surface is needed. It still retains the inherent strength of the expanded process but with a totally different look and feel.

Beyond diamonds, modern machinery can create custom patterns—hexagons, circles, or complex artistic designs. This pushes expanded metal mesh from a purely industrial product into the realm of architectural art. The “S-Shaped Metal Mesh Curtains” or “Decorative Woven Grilles Brass Strip Wire Mesh Panels” you might see on a building facade are testaments to this capability. These designs play with light, shadow, and visibility, offering sun control, privacy, and breathtaking aesthetics all at once.

Where It All Comes Together: Real-World Applications

So, where does this transformed material end up? The journey from raw sheet to functional mesh culminates in its installation across our built environment. The applications are as diverse as the materials and patterns themselves.

In architecture and construction, expanded metal mesh is a designer’s versatile tool. It’s used as stunning decorative cladding and sunscreens on building exteriors, creating dynamic facades that change with the light. Inside, it becomes elegant ceiling panels, room dividers, and balcony infill, providing visual interest without closing off space. Its strength makes it perfect for sturdy yet airy stair treads and safety guards, as hinted at by the “Decorative Galvanized Perforated Metal Sheet for Stair” product listing.

The industrial sector relies on its durability and safety. You’ll find heavy-duty expanded metal mesh as platform grating, machine guards, and safety fences in factories and plants. Its open area allows for the passage of light, air, and sound, while its rigidity can support significant weight. In filtration and screening, specific gauges and openings of expanded metal mesh are used to sort aggregates, filter materials, and shield components.

Even in consumer and specialty applications, it’s everywhere. That sturdy shelf in your storage shed? Likely expanded metal. The grille on a speaker, the backing in a radiator guard, the basket in a deep fryer, or the reinforcement in stucco walls (as lath). Its unique combination of strength, airflow, and formability makes it an irreplaceable solution for countless engineering challenges.

Wrapping It Up

From its start as a humble sheet of metal to its final form as a vital component in buildings, machines, and everyday objects, the story of expanded metal mesh is a testament to ingenious manufacturing. The expansion process creates something stronger and more versatile than the sum of its parts, all while honoring the material with zero waste. By understanding the dance between the stretching press and the properties of metals like stainless steel, aluminum, and galvanized steel, we can specify the perfect mesh for the job—whether it’s to catch the light on a museum wall or to safely bear the weight of a worker on an industrial platform. It’s a material that truly proves that transformation—not removal—is the key to strength and functionality.

Comments are closed.