Ensuring that a building is safe and in good condition is crucial for the safety and well-being of its occupants. Building assessment and evaluation is a process that is carried out to identify potential risks and hazards in buildings, and to evaluate their overall condition. This process can be complex and challenging, but with the right knowledge and expertise, it can be carried out effectively. In this article, we will explore some common mistakes to avoid when carrying out building assessment & evaluation in Singapore.

Understanding the Importance of Building Assessment and Evaluation

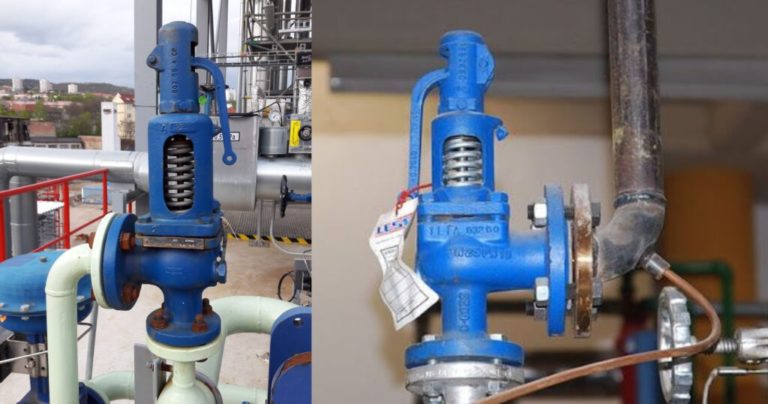

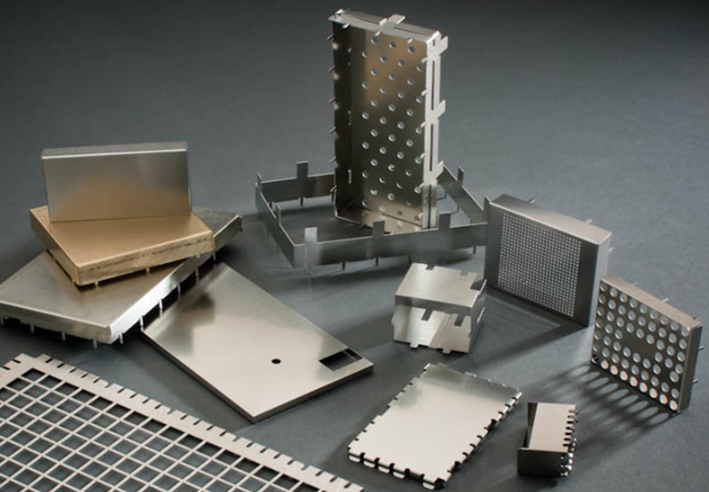

Building assessment and evaluation is an important process that is carried out to ensure that buildings are safe and in good condition. It involves inspecting various aspects of a building, such as its structure, electrical and mechanical systems, and fire safety systems, among others. By carrying out regular building assessment and evaluation, potential risks and hazards can be identified and addressed in a timely manner, thereby minimizing the risk of accidents and ensuring the safety of the occupants.

Common Mistakes to Avoid

While building assessment and evaluation is a crucial process, there are some common mistakes that people tend to make. Here are some of them:

- Not Hiring a Professional: Building assessment and evaluation is a complex process that requires the right expertise and knowledge. Attempting to carry it out without the necessary expertise can lead to mistakes and oversights, which can be costly and dangerous in the long run.

- Not Carrying Out Regular Inspections: Regular inspections are necessary to ensure that potential risks and hazards are identified and addressed in a timely manner. Failing to carry out regular inspections can result in the identification of risks and hazards only after they have caused damage or harm.

- Not Addressing Identified Risks and Hazards: Identifying risks and hazards is only the first step in the process. It is important to address them in a timely and effective manner to ensure the safety of the building’s occupants.

Seeking Professional Assistance

Carrying out building assessment and evaluation can be complex and challenging. It requires the right expertise, knowledge, and tools. To ensure that the process is carried out effectively and efficiently, it is important to seek the assistance of a corporate service provider. B2S Specialist Pte Ltd is a trusted and reliable rope access company in Singapore that provides professional building assessment and evaluation services. With their expertise and knowledge, they can help you avoid the common mistakes and ensure that your building is safe and in good condition.

Conclusion

Building assessment and evaluation is a crucial process that should not be taken lightly. By avoiding common mistakes, and seeking professional assistance from a corporate service provider like B2S Specialist Pte Ltd, you can ensure that your building is safe and in good condition. Remember, the safety and well-being of the occupants should always be a top priority.

“Carrying out regular inspections may seem tedious, but it is crucial in identifying and addressing potential risks and hazards in a timely manner.”

Reference:

Building and Construction Authority Singapore. (2022). Building Maintenance and Strata Management Act. Retrieved from https://www.bca.gov.sg/building-maintenance/legislation/bmsma