The construction industry is always evolving, seeking innovative techniques to build stronger, more durable, and efficient structures. Among the various advancements, the introduction of headed bars as a reinforcement method has gained significant traction. Headed bars, also known as deformed bars with enlarged heads, are a type of reinforcement bar (rebar) used to enhance the strength and stability of concrete structures. The distinctive feature of headed bars is the presence of bulbous heads or deformations at regular intervals along the length of the bar.

Advantages of headed bars:

- Improved bond strength – One key advantage of headed bars is their superior bond strength with concrete. The enlarged heads act as anchors, providing a significantly larger surface area for the concrete to grip onto. This mechanical interlock between the heads and the concrete creates a stronger and more durable bond than traditional plain round bars. The increased bond strength prevents slippage and ensures a more unified behaviour between the reinforcement and the concrete, enhancing the overall structural integrity.

- Reduced slippage and corrosion risk – headed bars excel in minimising the risk of slippage and corrosion, which are common challenges with traditional reinforcement methods. The unique head design provides a more secure anchorage within the concrete, reducing the likelihood of movement under loading or environmental stresses. The mechanical lock created by the heads firmly holds the reinforcement, preventing the bars from sliding or pulling out of position. This secure anchorage also reduces the potential for corrosion, as it limits the exposure of the steel to moisture and aggressive chemicals.

- Enhanced load-bearing capacity – Headed bars offer improved load-bearing capacity, allowing structures to withstand greater weights and forces. The enlarged heads effectively distribute tensile forces along the bar, enhancing ductility and deformation capacity. With headed bars, engineers can design longer spans, utilise thinner concrete sections, and reduce the overall material usage without compromising the structural strength. In projects requiring material optimisation, this results in more efficient, cost-effective designs.

- Superior shear resistance – Headed bars exhibit exceptional shear resistance, a critical factor in preventing structural failures. The heads create a “plug” effect within the concrete, effectively interlocking with the surrounding matrix. This mechanical interlock prevents the propagation of cracks and distributes shear forces evenly throughout the structure. As a result, headed bars enhance the overall shear strength and improve the durability and longevity of the building.

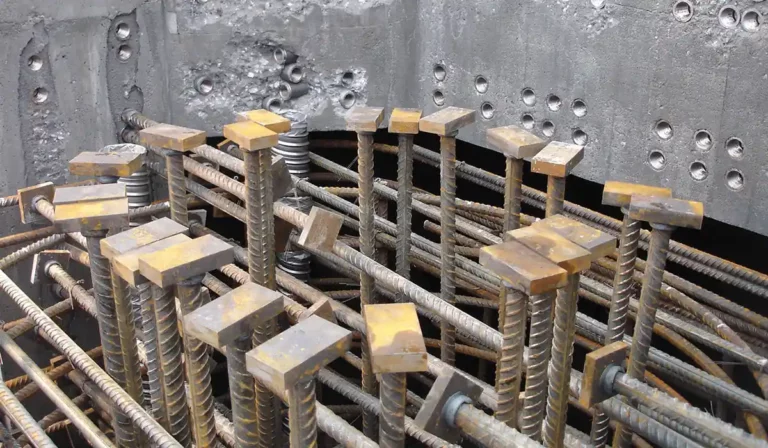

- Faster and simplified installation – The installation process for headed bars is notably faster and more straightforward than traditional reinforcement methods. The heads naturally maintain the appropriate spacing between bars, eliminating the need for manual tying or positioning, which is time-consuming and labour-intensive. Additionally, the heads act as a built-in chairing system, ensuring the bars remain at the correct elevation during placement. This streamlined installation process reduces labour costs, speeds up construction timelines, and minimises the risk of installation errors.

- Versatility in design – Headed bars offer design versatility, making them suitable for various applications. They can be customised to meet specific project requirements, including varying head sizes, spacing, and bar diameters. This adaptability allows engineers and designers to tailor the reinforcement to the unique needs of each structure, optimising its performance. Headed bars can be used in slabs, beams, columns, and foundations, providing a versatile reinforcement solution for various structural elements.

Headed bars offer a compelling range of advantages over traditional reinforcement methods in construction buildings. Reinforced concrete structures will continue to benefit from headed bars as the construction industry embraces innovation.

Comments are closed.