Recycling of foil converter can save significant amount of the energy needed to make the metal from raw materials. Recycling and refining of the foil converts can prevent the accumulation of the waste on the landfill. Scrap recycling industries are flourishing across the globe. Whether you are wholesale or non-wholesale scarp foil converter seller with the reliable and professional foil converter processing company you can consistently get handsome payout at the same time can contribute to the environment. Most of the foil converter processing companies with their years of experienced, highly skillful professionals and cutting-edge technology can recycle the foil converter efficiently and recover the precious metals at higher amount.

Catalytic Converters

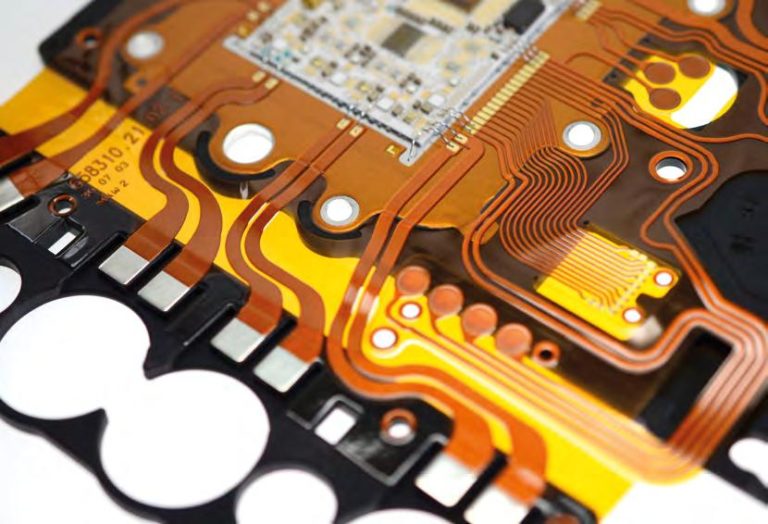

The catalytic converters for vehicle use consist normally of an active catalytic material in a specifically made steel housing which directs the exhaust gas circulation with the driver bed. The driver is generally made up of a little mass of active material such as noble metal, or a mix of change as well as non-transition steels, deposited on thermally steady support products such as alumina.

Evaluate the credibility

In today’s digital era, you are able to conveniently search for the best foil converter recycling companies online. Go through the websites of few reputable companies and then get relevant information such as range of services offered, speed of payout, transparency while providing comparative count, a complete weight report, a weight breakdown, assay report, etc. Regardless of your location you can avail the transport and storage services of the company and can sell your scarp with great ease. To maintain the transparency of the process system many companies encourage suppliers to visit their facilities and be aware of the method followed by the company for catalytic converter and foil converter refining.

Promote refining

Catalytic converters are widely used in vehicles to reduce the amount of emission of harmful toxic in the air. To build the catalytic converter many precious metals have been used such as platinum, rhodium, palladium, metal foils, etc. consequently the demand for the PGM is always at high. If you recycle the catalytic converters it reduces the need to pull additional resources from the environment. PGM production is time consuming and stressful process that involves erase of processes such as such as mining operation, flotation, smelting, converting, leaching, purification, etc. Hence promote recycling and prevent the disturbance of the natural.

Comments are closed.